Igwe eji agbado ọkụ laser ejiri aka maka igwe anaghị agba nchara aluminom

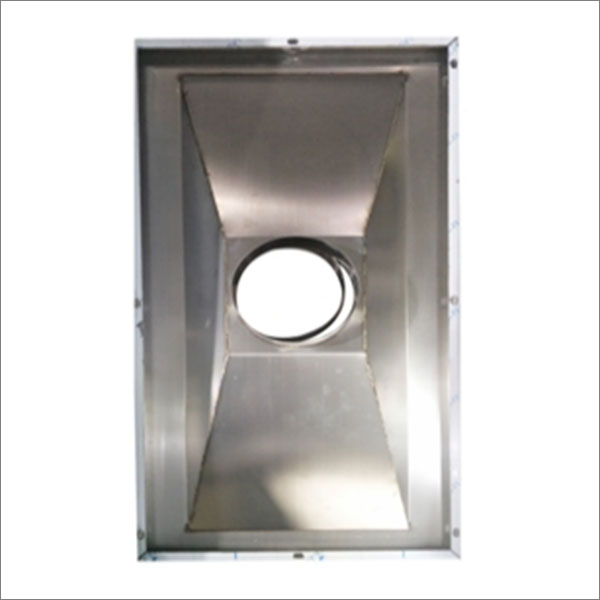

Igwe ịgbado ọkụ laser ejiri aka, na-eji generator laser kachasị ọhụrụ.Ejikwa isi wobble na waya filler kwadoro ya.Igwe ndị ahụ na-apụta na ụlọ ọrụ akụrụngwa laser, na-ejuputa oghere nke ịgbado ọkụ aka.Ọ nwere uru nke ọrụ dị mfe, ọmarịcha ọkụ ịgbado ọkụ na ọsọ ịgbado ọkụ ngwa ngwa.Welding na mkpa aluminum, igwe anaghị agba nchara mpempe akwụkwọ, ígwè mpempe akwụkwọ, galvanized mpempe akwụkwọ na ndị ọzọ metal ihe nwere ike n'ụzọ zuru okè dochie omenala argon arc ịgbado ọkụ, eletriki ịgbado ọkụ na ndị ọzọ Filiks.Enwere ike iji igwe ịgbado ọkụ laser ejiri aka mee ihe na kọbọd, kichin, steepụ, igwe mbuli elu, racks, oven, ọnụ ụzọ igwe anaghị agba nchara na windo nchekwa, igbe nkesa, ụlọ igwe anaghị agba nchara na ụlọ ọrụ ndị ọzọ siri ike na usoro ịgbado ọkụ na-adịghị mma.

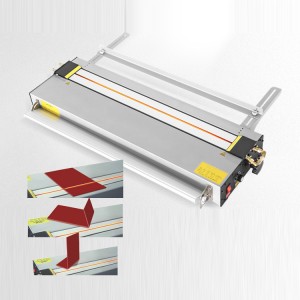

| 1 | Ụdị igwe | Igwe ịgbado ọkụ eriri laser ejiri aka |

| 2 | ike laser | 1000W, 1500W, 2000W, 3000W |

| 3 | ogologo ebili mmiri laser | 1070 NM |

| 4 | Ogologo eriri | Ọkọlọtọ10M Kachasị 15M |

| 5 | arụ ọrụ mode | Nga n'ihu / modulate |

| 6 | Oke ịgbado ọkụ | 0 ~ 120 mm / s |

| 7 | Igwe oyi na-atụ oyi | Ụlọ ọrụ mmiri chiller |

| 8 | Oke ọnọdụ okpomọkụ na-arụ ọrụ | 15-35 ℃ |

| 9 | Oke iru mmiri nke gburugburu ebe ọrụ | <70% Enweghị condensation |

| 10 | Welding ọkpụrụkpụ tụrụ aro | 0.5-3 mm |

| 11 | chọrọ oghere ịgbado ọkụ | ≤0.5mm |

| 12 | voltaji arụ ọrụ | 220 V |

Enwere ike iji ya mee ihe na kabinet, kichin, igwe elu steepụ, shelf, oven, ọnụ ụzọ igwe anaghị agba nchara na nchekwa windo, igbe nkesa, ụlọ igwe anaghị agba nchara na ụlọ ọrụ ndị ọzọ siri ike na usoro ịgbado ọkụ oge niile.

Ọsọ ịgbado ọkụ bụ ugboro 2-10 ngwa ngwa karịa ịgbado ọkụ ọdịnala.Otu igwe nwere ike ịchekwa opekata mpe abụọ welders kwa afọ.

Mgbado ọkụ laser

ịgbado ọkụ ọdịnala

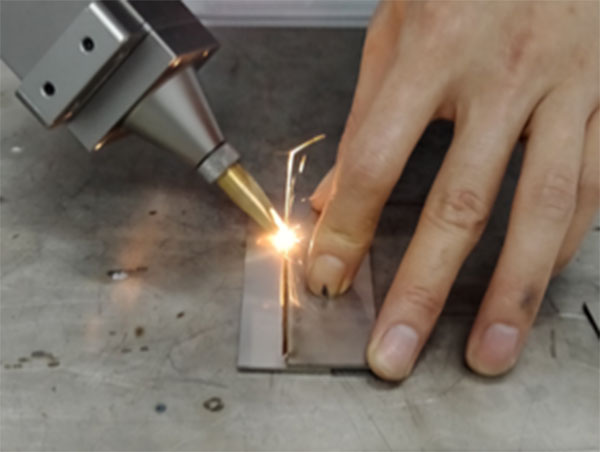

► Ọrụ ahụ dị mfe, ọ ga-ekwe omume ịbanye n'ọrụ na-enweghị akwụkwọ ọrụ, na ngwaahịa mara mma nwere ike ịgbanye n'enweghị onye nkụzi.

Mgbado ọkụ fillet, ịgbado ọkụ kwụ ọtọ

Ịkwado ịgbado ọkụ

Machie ịgbado ọkụ

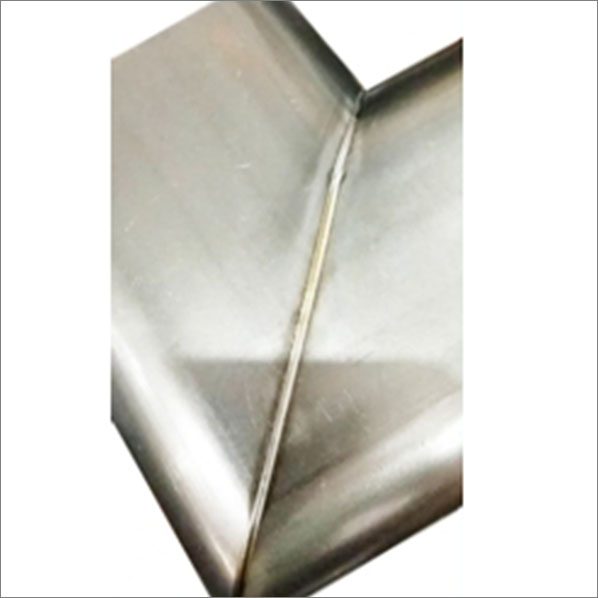

Ihe nkedo weld dị mma ma mara mma, na-ebelata usoro ịkụcha ihe na-esote, na-azọpụta oge na ọnụ ahịa.

Enweghị ọnyà ịgbado ọkụ

Weld mara mma

Enweghị deformation nke workpiece

The onwe-mepụtaraWisi ịgbado ọkụ obble na-akwụ ụgwọ maka mwepu nke laser ịgbado ọkụ obere ntụpọ, gbasaa ndidi nso nke machined akụkụ na weld obosara, na-enweta mma weld guzobe.

The ịgbado ọkụ workpiece enweghị deformation, ọ dịghị ịgbado ọkụọnya, na ịgbado ọkụ siri ike.

Ịgbado ọkụ laser nwere obere ihe oriri na ogologo ndụ.

Dị nchebe na karịa gburugburu ebe obibi.